Investment Casting

NEWS, BLOGS & EBOOKS

Overview

Auto-Way is ranked among the Top 100 investment casting manufacturers in China. Investment casting is Auto-Way’s largest business segment and will continue to be our core business segment.

Process Introduction

Investment casting is one of the most sophisticated casting processes, enabling intricate shapes while still maintaining high dimensional accuracy and high surface quality. Investment casting can be used to cast almost any metal satisfying application requirements in diverse end-markets.

Equipment

At Auto-Way, we employ the latest in advanced technology and cutting-edge process equipment at various investment casting process phases. Tooling design, wax pattern injection, wax pattern assembly, shell-making, pouring, heat treatment, and testing are all performed using the best available machinery, operated by our qualified team of experts.

Materials

Auto-Way is capable of meeting material specifications according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, and GB standards. We cast more than 100 different ferrous and nonferrous alloys.

Capabilities

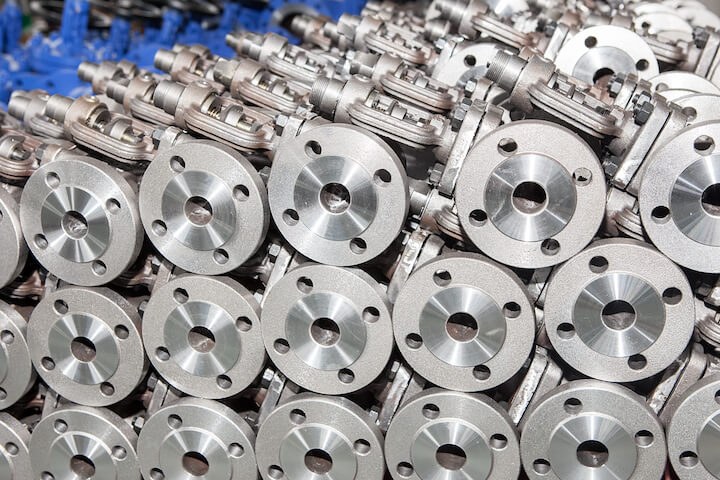

Auto-Way investment casting capabilities cover both ferrous and nonferrous metals. We produce high precision and geometrically complex investment castings ranging from a few ounces up to 220 lbs. and up to 40 ins. in diameter or length, utilizing both air and vacuum melting and pouring technologies.

3D Printing Technology

3D printing technology is the perfect cost-effective and efficient solution for rapid prototyping and small production runs. At Auto-Way, we use 3D printing to develop complex investment castings that require design alterations or are under a tight deadline.

Typical Products

Auto-Way manufactures investment castings for diverse end markets. Typical products include high-pressure common rail parts, rocker arms, nozzle rings and turbine scroll for automotive applications, manifolds, housings, brackets for industrial equipment applications…