Marine

Marine components operate in demanding environmental conditions and play mission-critical roles in marine systems. These components must deliver consistent and reliable performance, even in high-stress environments.

Auto-Way is your trusted partner in this specialized field, offering a wide range of manufacturing technologies, including precision machining, investment casting, permanent mold casting, and shell mold casting, to create Marine components that adhere to industry standards. Additionally, we provide in-house heat treatments, surface treatments, and a comprehensive suite of inspection and testing services, all geared towards ensuring product quality.

Our commitment to delivering excellence extends to offering one-stop-shop solutions. We take pride in supplying high-quality parts at competitive costs, always delivered on time. Our capabilities encompass:

- CNC precision machining (4-axis and 5-axis equipment) for stainless steel, alloy steel, aluminum, superalloys, and titanium to make parts from plates, billets, bar stocks, and forgings

- Investment casting for aluminum, low alloy steel, stainless steel, Nickel and Cobalt-based superalloys and titanium in sizes ranging from a few ounces to 100 pounds

- Permanent mold casting for aluminum parts up to 16 inches in diameter or length and 35 pounds in weight

- Shell mold casting for aluminum parts up to 12 inches in diameter or length and 30 pounds in weight

- Heat treatments including vacuum gas cooling, vacuum oil cooling, aluminum alloy heat treating, gas nitriding, cold stabilization, stress-relieving and tempering and aging

- Surface treatments, such as anodizing, chemical conversion coating, passivation, plating, stress, and embrittlement relief, etching, painting and dry film application

- NDT and laboratory testing including X-ray analysis, fluorescent penetrant inspection and magnetic particle inspection

We are your premier source for Marine components, manufacturing and supplying investment castings, permanent mold castings, shell mold castings, and precision machined parts tailored specifically for Marine applications.

Marine Investment Casting Capabilities

At Auto-Way, our investment casting process boasts exceptional versatility, allowing us to pour a diverse range of metals commonly used in Marine applications. This includes stainless steel, superalloys, aluminum, and titanium, all meticulously crafted to meet the stringent standards of Marine parts.

Typical Marine Investment Casting Products

- Valve mounts

- Swirl nozzle

- Engine rings

- Body and assemblies

- Seat and assemblies

- Manifold and assemblies

- Cooling Tubes

- Mounting Brackets and Flanges

- Retainer Seal

Marine Precision Machining Capabilities

Auto-Way’s precision machining methods bring a multitude of benefits to customers seeking Marine components with exacting requirements for close tolerance and surface finish. Our comprehensive precision machining process capabilities encompass CNC turning, vertical/horizontal milling, grinding, and more. When it comes to delivering high-quality Marine components at competitive prices, our precision machining methods consistently yield impeccable results.

Typical Marine Precision Machining Products

- Motor Housings

- Port Caps

- Valve Seats

- Flanges

- Adapters

- Rod Ends

- Piston

- Discharge Fitting

- Canister Covers

- Lever

- Plunger

- Gasket

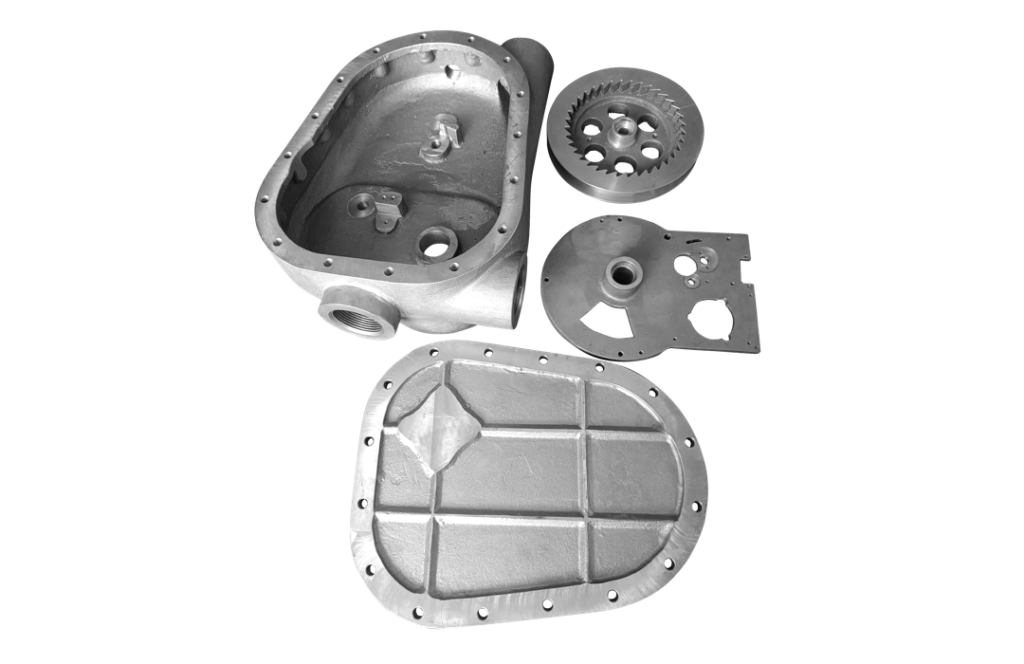

Marine Permanent Mold and Shell Mold Aluminum Casting Capabilities

Auto-Way’s permanent mold and shell mold casting capabilities empower us to produce highly accurate components, even with complex geometric structures. Our proficiency in these processes ensures the timely delivery of high-quality parts that not only meet but exceed our customers’ expectations.

Marine Permanent Mold and Shell Mold Aluminum Casting Capabilities

- Front Housing Assembly

- Housing

- Flange Mounting

- Impeller

- Flange Housing

When you seek Marine parts that are built for durability and reliability, rely on the convenience of Auto-Way’s one-stop-shop capabilities.