Medical

Precision and reliability are paramount when it comes to parts for medical applications. At Auto-Way, we excel in the production and supply of investment castings, sand castings, and precision machined components specifically tailored for diagnostic equipment, surgical instruments, biosystem equipment, prosthetics, and patient handling equipment.

Materials Used for Medical Casting and Precision Machining Parts

Materials for medical components must meet stringent safety requirements, ensuring they are not only hard-wearing but also corrosion-resistant and fatigue-resistant, especially when used in load-bearing applications. At Auto-Way, we offer a wide range of materials, including anodized aluminum, cobalt chrome alloys, 6AL4V titanium, 316 and 17-4 precipitation-hardened stainless steels. These materials are carefully chosen for their durability, corrosion resistance, and safety in human contact.

In the medical field, components often undergo rigorous sterilization and cleaning processes, such as peracetic acid or hydrogen peroxide treatments, which can strip off paints and coatings. Many of our components are left uncoated to prevent any risk of flaking during use. Our equipment also provides smooth surface finishes, reducing the need for additional grinding and polishing processes. Through meticulous material selection, we ensure that our components are not only safe but also built to last.

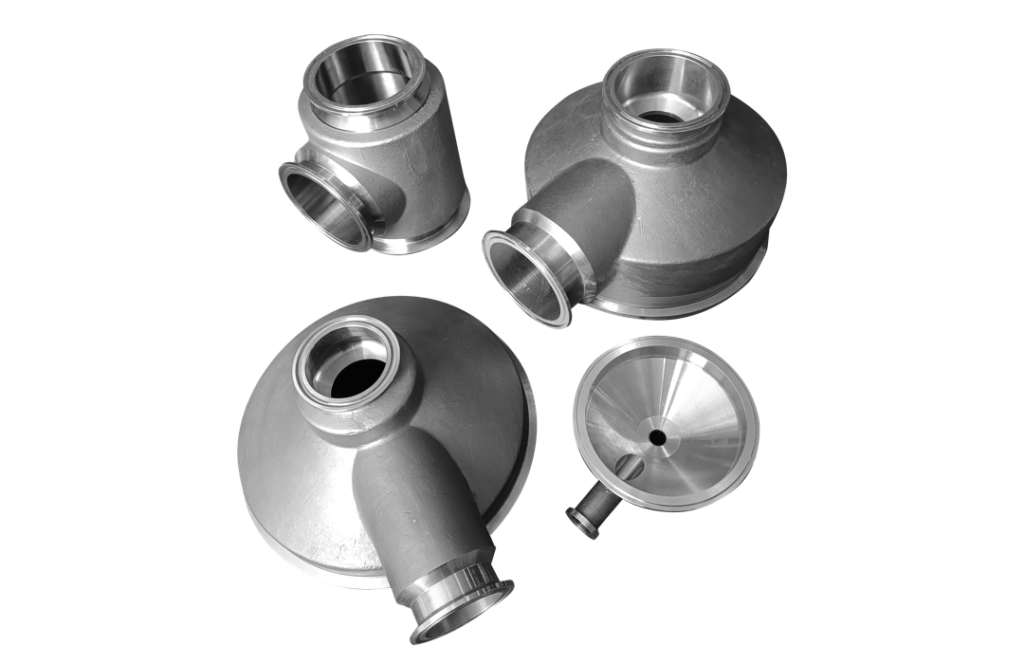

Medical Products Made by Investment Casting

Auto-Way boasts extensive experience in manufacturing a wide range of components for various types of medical devices using investment casting processes. These components include:

- Mount Housing

- Flange Pivot

- Caster Mount

- Guide

- Support Block

- Bracket

- Hinge Block

- Radial Support

These precision components find vital applications in a diverse range of end-use scenarios, including:

- Diagnostic Equipment

- Surgical Instruments

- Biosystem Equipment

- Prosthetics

- Patient Handling Equipment

- Implants

Medical Products Made by Precision Machining

Our precision machining processes set the industry standard for medical component manufacturing. Customers benefit from our expertise in precision machining, which delivers components with the following key advantages:

- Fine Details: Our machining processes ensure that even the finest details of medical components are accurately reproduced.

- High Dimensional Accuracy: We uphold the strictest dimensional accuracy standards, ensuring that components meet precise specifications.

- Durability: Medical components produced through our machining processes are built to last, with exceptional strength and longevity.

We employ top-quality machine tools and expert cutting tool selection and usage to consistently deliver medical components that meet and exceed the highest industry standards for quality and performance.

- Elbow Shaft

- Pin Connector

- Block, Threaded-Lifting

- Rod End Link

- Clamp Cap

Medical Products Made by Sand Casting

Auto-Way’s resin sand casting process is instrumental in producing a wide range of structural components for heavy equipment, such as machine bases, equipment frames, and more. These parts exhibit the following characteristics:

- Substantial Weight: Our process can handle parts ranging from a few hundred pounds to several tons, providing versatility for various applications.

- Complex Structure: We excel in manufacturing components with intricate and complex structures, meeting the most demanding design requirements.

- High Dimensional Accuracy: Our commitment to precision ensures that every component meets precise dimensional specifications.

- Special Surface Treatment: Certain applications require unique surface treatments, and we have the capabilities to accommodate these requirements.

At Auto-Way, our integrated approach ensures that all manufacturing stages, from design to production, take place under one roof. This approach not only guarantees quality but also enables us to meet customer expectations in terms of lead time and delivery.”